ENERGY / POWER

Carbon electrospun nanofiber for supercapacitor

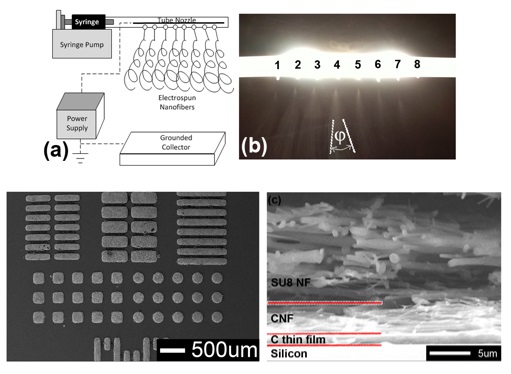

Carbon nanofiber derived from electrospun SU-8 nanofibers are advantageous due to their large surface area, chemical resistivity and lower resistivity. The research focuses on increasing the throughput production of electrospun nanofibers using tube nozzle electrospinning (TNE) shown in figure, wherein multiple nozzles increases jetting sources for the polymer. Additionally electrospun SU-8 nanofibers can be photopatterned using UV lithography to give patterned carbon nanofibers. By stacking layers are carbon nanofibers and SU-8, a supercapacitor is fabricated with all-nanofiber architecture.

(a) Schematic of the multi-nozzle electrospinning setup. (b) Optical image of the multinozzle electrospinning setup during operation. (c) SEM of the deposited nanofiber after patterning. (d) SEM of the cross section of the layered nanofiber.

Power management system

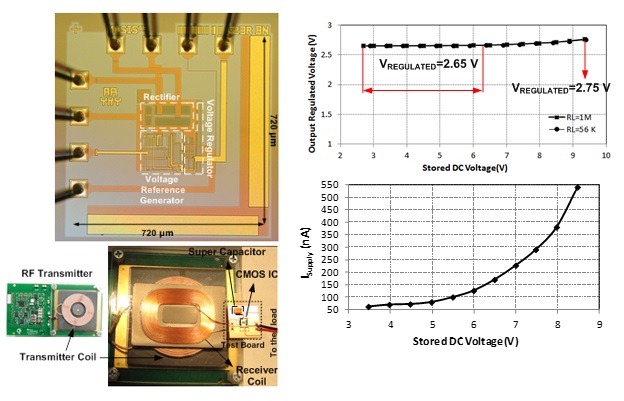

An ultra-low power and fully integrated power management unit is demonstrated in standard CMOS process for near-field RF power transmission and energy harvesting. The presented architecture consists of a highly efficient rectifier, a sub-threshold reference voltage generator and a voltage regulator using the ONSemi 0.5 µm CMOS process. The implemented test system composed of an RF energy harvesting coil, the fabricated IC, and a storage element is able to generate a 2.65–2.75 V regulated output for a broad input range of 2.5–9.5 V AC peaks, with a load current of 2–100 µA and a current consumption for the unit of less than 550 nA. This small quiescent current consumption makes the total unit a suitable candidate for energy harvesting and battery-free applications.

(Left) Optical images of the die and measurement setup. (Right) Graphs showing ther performance of the fabricated wireless power management system.